Special Spring Collet In Ambattur Industrial Eastate

Special Spring Collet In Ambattur Industrial Eastate In the precision machining industry, the need for reliable, accurate, and efficient tools is paramount. Special spring collets have emerged as a revolutionary innovation, offering unmatched clamping force and flexibility. This article explores the features, advantages, applications, and recent developments in special spring collets, highlighting their impact on modern machining processes.

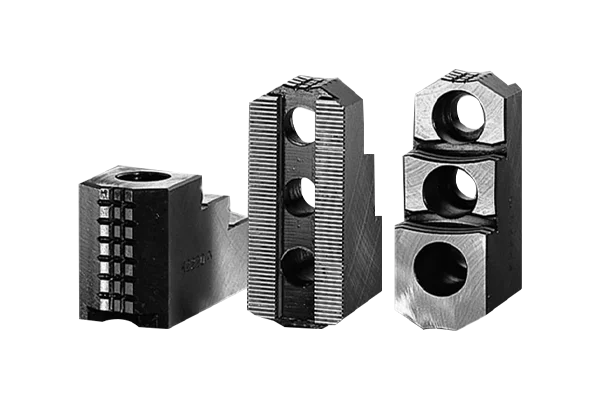

Understanding Special Spring Collets

Special spring collets are a type of tool holder designed to securely grip tools or workpieces with high precision. They incorporate a spring mechanism that allows them to expand and contract, providing a firm and adjustable grip. This flexibility ensures that the collets can accommodate slight variations in tool or workpiece dimensions, maintaining a secure hold throughout the machining process.

Key Features of Special Spring Collets

- Spring Mechanism: The core feature of these collets is the spring mechanism, which provides a flexible yet firm grip.

- High Clamping Force: The design allows for a high clamping force, ensuring that the tool or workpiece remains securely in place.

- Durability: Made from high-quality materials, special spring collets are built to withstand the demands of rigorous machining operations.

- Precision Fit: The adjustable nature of the spring mechanism ensures a precise fit, reducing the risk of slippage or movement.

- Versatility: These collets can accommodate a range of tool and workpiece sizes, making them suitable for various applications.

Advantages of Special Spring Collets

- Enhanced Accuracy: The secure grip provided by the spring mechanism improves machining accuracy and quality.

- Increased Efficiency: Special spring collets minimize setup times and enable quick tool changes, enhancing overall machining efficiency.

- Flexibility: The ability to adjust to different sizes and shapes makes these collets highly versatile.

- Reduced Wear: The even distribution of clamping force reduces wear and tear on tools, extending their lifespan.

- Cost Savings: The precision and efficiency provided by special spring collets can lead to significant cost savings over time.

Applications of Special Spring Collets

Special spring collets are used in a variety of industries due to their precision and adaptability:

- Aerospace Industry: Essential for producing high-precision components for aircraft and spacecraft, where accuracy and reliability are critical.

- Automotive Industry: Used in the manufacturing of engine components, transmission parts, and other critical automotive parts that require precision and durability.

- Medical Device Manufacturing: Crucial in the production of medical devices that demand high precision and reliability.

- Electronics Industry: Used in the manufacturing of electronic components, such as circuit boards and connectors, where delicate handling is necessary.

- General Machining: Applicable in various general machining tasks, including milling, turning, drilling, and grinding.

Recent Innovations in Special Spring Collets

Technological advancements have led to significant innovations in the design and manufacturing of special spring collets:

- Advanced Materials: The use of high-performance alloys, composites, and specialized coatings enhances the durability and performance of these collets.

- Precision Manufacturing: Modern manufacturing techniques, such as CNC machining and additive manufacturing, allow for the production of collets with extremely tight tolerances, improving their precision and reliability.

- Custom Designs: The ability to design and manufacture custom collets tailored to specific applications provides even greater flexibility and performance.

- Enhanced Spring Mechanisms: Innovations in spring technology ensure that these collets provide an even more secure hold, reducing the risk of slippage and improving accuracy.

Case Studies Highlighting the Impact of Special Spring Collets

- Aerospace Component Manufacturing: A leading aerospace company adopted special spring collets for manufacturing turbine blades. The result was a 20% increase in production efficiency and a 15% improvement in part accuracy.

- Automotive Industry: An automotive parts manufacturer implemented high-torque special spring collets for engine part machining. This led to a 25% reduction in machining time and a significant improvement in surface finish.

- Medical Device Production: A medical device company utilized micro special spring collets for producing intricate components. This resulted in enhanced precision and reliability, meeting stringent industry standards.

Expert Insights on the Future of Special Spring Collets

Industry experts predict that the demand for special spring collets will continue to rise as machining processes become more complex and precise. The ongoing advancements in materials science and manufacturing technologies are expected to further enhance the capabilities of special spring collets, making them even more indispensable in the future.

Dr. Emily Foster, a renowned expert in precision machining, states, “The evolution of special spring collets is a testament to the industry’s commitment to achieving higher precision and efficiency. As we continue to push the boundaries of what is possible, special spring collets will play a pivotal role in shaping the future of machining.”

Maintenance and Care for Special Spring Collets

To ensure the longevity and performance of special spring collets, proper maintenance and care are essential:

- Regular Cleaning: Keep collets clean to prevent debris from affecting their clamping ability.

- Inspection for Wear: Regularly inspect collets for signs of wear or damage and replace them as needed to maintain accuracy.

- Proper Storage: Store collets in a clean, dry environment to prevent rust and corrosion.

- Lubrication: Apply a light coat of lubricant to moving parts to reduce friction and wear, if recommended by the manufacturer.

Conclusion

Special spring collets represent a significant advancement in precision machining, offering unparalleled accuracy, flexibility, and efficiency. By understanding their features, advantages, and applications, and by selecting the right type for your needs, you can significantly enhance your machining processes. With ongoing innovations in materials and manufacturing techniques, special spring collets continue to evolve, providing even greater capabilities for high-precision machining tasks.